|

Technical characterictics

|

||||||||||||||||||

The milling plant is meant to mill basic materials with hardness up to 6 of Mohs scale.

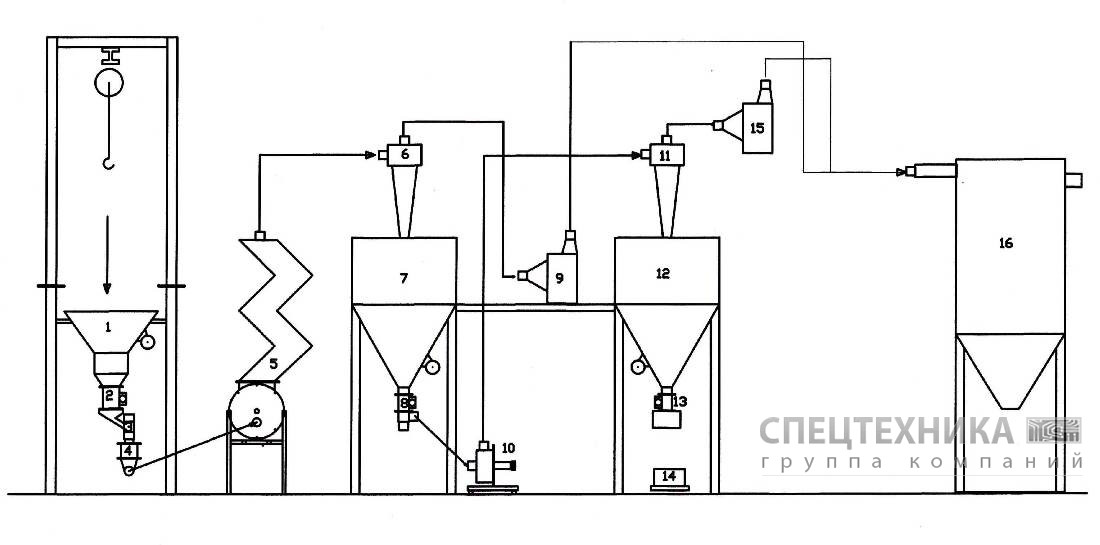

The plant operates the following way:

Unit of materials preparation.

Basic materials in big-bag come to a bag breaker equipped with vibrator 1 From there it is portioned by sluice transfer 2 into hammer mill 3 for coarse milling. Milled material passes though magnetic separator 4 where it is cleaned from magnetic impurity. Further the material with the help of blower 9goes to grinder-separator 5, for additional grinding and separation of sand and other impurity. Cleaned milled material is picked up by cyclone 6 . Finished material accumulates into bin 7 (vibrator, level sensor), where it can be stored or goes to milling unit by warm transfer 8. . Air, cleared from material, with residue of fine dust goes from cyclone outlet to bag filter 16. Settled into the filter material accumulates into filter bin.

Milling unit.

Prepared material from bin 7 by sluice transfer 8 is portioned to mill 10. The mill operates as an exhaust blower and picks up material together with required air quantity. From mill outlet milled material and air go under the force to cyclone 11. for settling. Settled material accumulates in finished product bin 12, Finished product is packed from bin by sluice transfer 13and balance system 14. Air, cleared from materials, with residue of fine dust goes from cyclone outlet by blower 15 to bag filter 16. Settled into the filter material accumulates into filter bin.

In order to avoid chocking-up the bag breaker, materials bin, finished product bin and bag filter are equipped with vibrators. Besides, materials bin and finished product bin are equipped with level sensors to control bin overfill and automatic power-off (sluice valve-1, sluice valve-2). The balance system automatically turns off a bag filling upon achievement of given weight.

Also the plant is equipped with an alarm system for lights and sound warning if case of emergency. Plant technological scheme is shown on picture.