The group of companies “ SPECTECHNIKA” offers a new approach to tyres thermal recycling technology. It considers the Customer’s interest only – low costs and high profitability.

This pyrolysis tyres recycling technology was tested on a certified industrial complex, which operates at tyres recycling enterprise..

Technology description

- Loading.

Innovation loading device allows to load tyres inside the reactor continuously in the auto mode, that increases efficiency and safety of the process.

- Pyrolysis process.

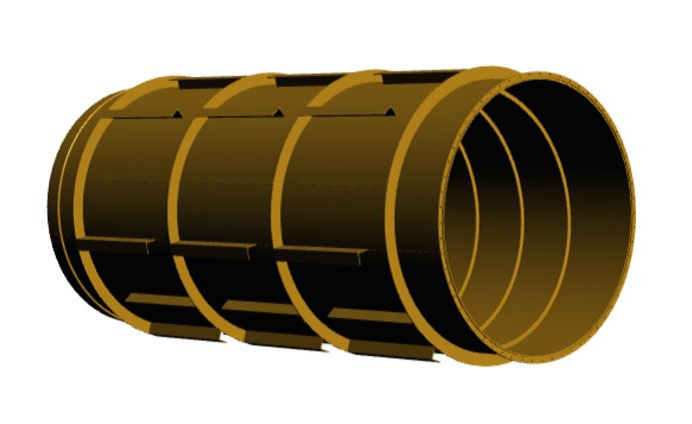

The construction is based on the method of pyrolysis with rotating drum. The permanent material rotation causes its uniform pyrolysis, process acceleration, carbon residue milling and metal cord separation by twisting it into a single bunch.

Materials are heated into a closed space without access for air. Organic compounds convert into synthesis gas and get into a condensation system.

At this step the materials are thermally treated into the reactor within 12 hours.

After cooling the most part of synthetic gas turns into a fuel oil. Fuel heavy fractions are separated in order to improve its liquidity and further using in diesel burners.

- Uploading of carbon residue and metal cord.

Uploading of carbon residue occurs just after the pyrolysis cycle, hermetically to outer aunger, after that it goes to storage capacitor for further cooling.

After long-time rotation of reactor the metal cord twists into a single compact bunch, easy for transportation. In order to avoid workshop dustiness during the unloading a screen is used. After the reactor the metal cord gets in pit and rolls down by angle subterranean base out of workshop, where it is washed by water from carbon dust and then it is ready for dispatch.

The main obstacle of industrial tyres pyrolysis recycling in Russia is inaccessibility of modern technology, that would make tyres recycling profitable. It even cannot be burned for energy usage – too much toxic gas segregates.

The company “SPECTECHNIKA” offers a recycling method that is new for Russia, and for that a special modern engineering and technology are designed.

Equipment for pyrolysis tyres recycling

Our technology provides total lack of noise, water conservation and minimum discharge into the atmosphere.

Main factors, that guarantee success of tyres pyrolysis recycling:

- State support;

- Free materials, always avaliable;

- Ecologically clean production, that is in demand on the market.

Call now or fill-in the online form to get a detailed consultation about tyres pyrolysis recycling.